Inflow (Negative) Testing –

Pub Date:Sep 26,2022 | Views:1781 |

Why Inflow (Negative) Testing?

When drilling the well and running tubulars, the drilling fluid will have a higher density than the reservoir/formation fluids to prevent any hydrocarbon influx. Prior to running in the production completion, the well is displaced to a lighter density completion fluid to encourage the hydrocarbons to flow into the wellbore and up the production tubing. If any integrity issues in the connections or the casing/liner overlap are present this could affect the overall efficiency of well production recovery, in addition to posing safety & integrity issues of the well construction. Hydrocarbons could potentially by-pass any safety related equipment in the well completion string.

How to Inflow (Negative) Testing?

By carrying out an inflow test, the well is allowed to go into an underbalanced state in a controlled manner, to check for any leaks in the liner tubular connections and/or the casing/liner overlap. As the well is not completely displaced to the completion fluid if any leaks were to be found the well can be kept under control at all times. The well can then be displaced back to the initial well fluid in a safe and controlled manner to allow remedial work to be carried out where required.

When Inflow (Negative) Testing?

A negative test can be carried out any stage of the well construction, but historically it is performed when the last production liner has been run and cemented in place. In recent applications it is also performed after running in a lower completion to test the integrity of a fluid-loss control valve.

Regardless of the end operation an inflow test should be carried out whenever the well is displaced from the initial well control, typically drilling mud fluid, to a lighter completion fluid.

How is Inflow (Negative) Test go through?

An Inflow Test can be carried out following the below simplified procedure:

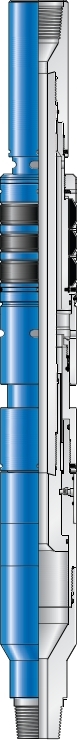

Pick up the inflow test packer and run as integral part of the main well bore clean up (WBCU) string.

Land out on the liner top to activate the inflow test packer

Apply weight to set the element, and carry out a positive integrity test on the annulus to ensure the inflow test packer doesn’t leak.

Pick up off the liner top and pump a pre-determined volume of the test fluid down the workstring.

Land back on the liner top to set the element to perform the inflow (negative) test for a minimum of four hours, or as per client’s requirements.

Unset the element and pick up off the liner top.

Reverse circulate the test fluid – can always pump the long way if desired.

Carry out the WBCU as per the program.