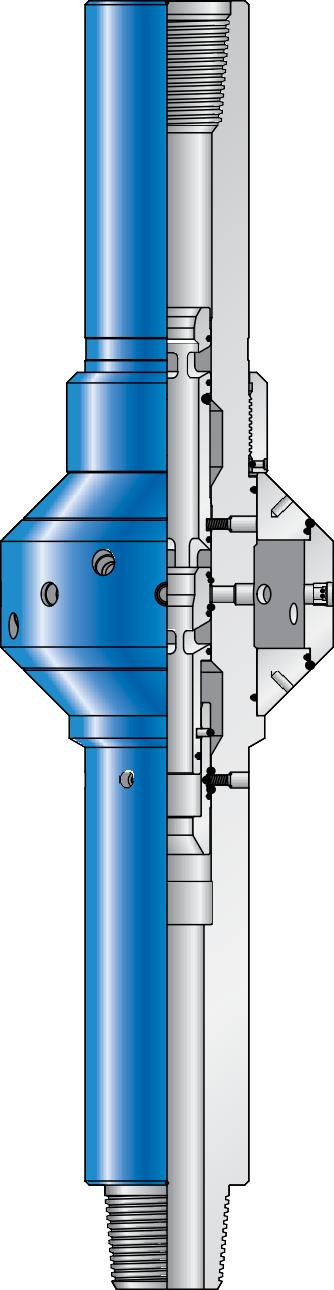

SP Downhole Magnet

Recover metal debris from wellbore with high-strength magnets

The Sharp Razor SP downhole magnet for deepwater, deep, and deviated well applications contains high-strength magnets that collect metal from the wellbore fluid and recover it to the surface. It removes ferrous metal debris left in the wellbore such as debris from window cutting, packer milling, or junk milling. It can be used by itself, with blowout preventer jet subs for blowout preventer cleaning, with VACS tools for downhole debris collection, or with other casing cleaning tools such as circulation subs, scrapers, brushes, and multi-task wellbore filters for wellbore cleaning and displacement.

The downhole magnet features one-piece mandrel design without any internal connection. The tensile and torque ratings of the tool are higher than those of the tool joint, which allows the tool to be used in deepwater wells, deep wells, or deviated wells in which higher tensile and torque ratings are required.

The high-temperature, high-strength magnets and unique magnet arrangement provide extraordinary metal debris capturing and carrying capability that is many times higher than a conventional tool, even in a high-pressure/high-temperature (HP/HT) well. The design lets metal debris tightly collect in the space between the magnetic bars, which allows adequate circulation area between the tool outside diameter and casing inside diameter. The robust

replaceable magnet bars can withstand harsh downhole environments and allow easy assembly, replacement, and tool cleaning.

The stabilizers at both ends of the tool centralize the tool and allow more effective circulation in the deviated wells. Allowing drillpipe to rotate up to 150 rpm could significantly increase cleaning efficiency and would also allow the tool to be used in the drilling or milling applications in which a high rotational speed is required.

The tool also provides large inside diameter and annulus flow areas. It allows more effective circulation and displacement operations.

Specifications

Tensile rating: higher than the tensile rating of tool joints

Torque rating: higher than the torque rating of tool joints

Allowable rotation speed: 150 rpm

Applications

Deepwater wells

Deep wells

Deviated wells

Extended-reach wells

HP/HT wells

Wells with high dogleg severity

Wells with excessive metal debris

Features and Benefits

High-strength rare earth magnets and unique magnet arrangement

Provides superior metal debris collecting capability

One-piece mandrel design with higher-than-tool-joints tensile and torque ratings

Provides a reliable and effective tool to clean wellbores and significantly mitigates completion and production risks and costs

Highest allowable rotation speed of 150 rpm

Increases cleaning efficiency

Non-rotating stabilizers

Effectively cleans well without damaging or wearing casing wall

Large circulation areas

Improves circulation and displacement efficiency

No exposed fasteners that could vibrate loose

Improves operational reliability