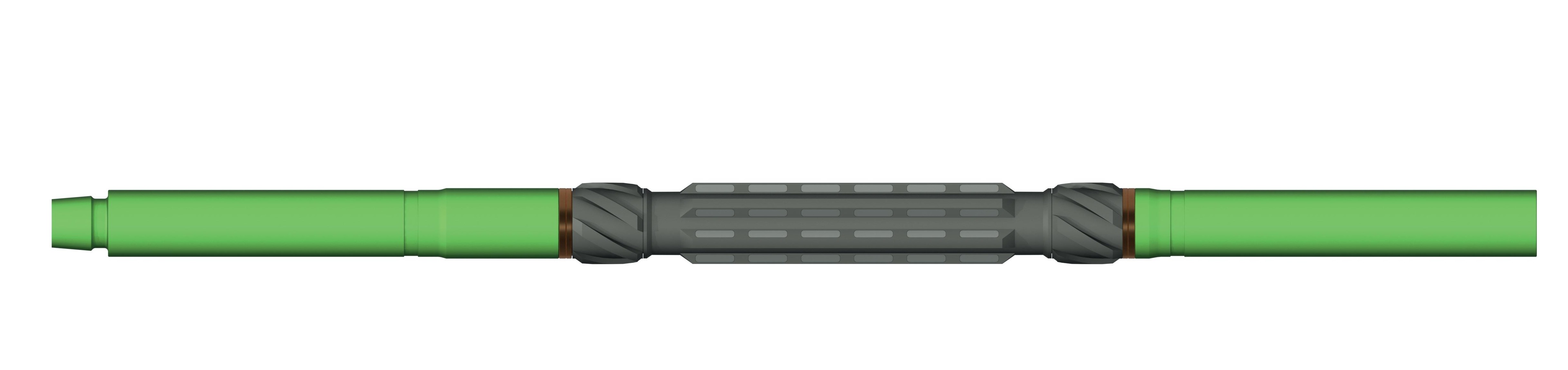

GVHD II-MagTM

The GVHD II-MagTM is a robust, non-rotating wellbore clean-up magnet suitable for all downhole conditions and with robust, high performance features.

Run separately or as part of a comprehensive wellbore clean-up, the GVHD II-MagTM is designed to effectively remove ferrous metal debris from the wellbore.

The external ribs with integral magnets are arranged to channel fluid through clearly defined flow paths. The magnet inserts capture metal debris and retain them securely for removal at surface.

The alloy bronze bearings feature both axial and radial elements to allow extended rotation in harsh environments, preventing tool and casing wear.

GVHD II-MagTM non-rotating ribbed magnet sleeve maximizes attraction and prevents debris fall-off

Non rotating design with high performance alloy bronze bearings compatible with high temperature and chemical applications

Rare earth magnet inserts can be provided in standard and high temperature variants

GVHD II-MagTM sleeve fully interchangeable with UNI-BLADE™ scraper and BRUSH

Available with all API and premium drill pipe connections

A properly executed wellbore clean-up mitigates risk during completion operations and the productivity of the well.

Prevent debris related premature packer setting while RIH

Prevent failure to set packers due to debris in the well

Prepare casing wall to ensure packer element sets and mitigate premature elastomer failure

Pre-completion wellbore clean-up

Workovers and sidetracking

Abandonment

Drilling / milling cement plugs

The GVHD II-MagTM can be run alone or as part of a comprehensive wellbore clean-up BHA. It is typically run in a BHA above a casing scraper and brushes as it complements the hard scraping action to remove rust and ferrous debris from the wellbore.

GVHD II-MagTM is centered in the casing by the integral GVHD II-MagTM sleeve with interchangeable non-rotating Centralizers. These guide and centralize the tool while allowing extended rotation without casing or tools wear.

While running in the hole or circulating, the well fluid passes along channels between the magnetized ribs capturing ferrous debris.

The ribs also prevent debris from being knocked off while circulating or tripping.

The robust tool design, non-rotating centralizers and large debris capacity allow milling of packers, or clean-up of casing windows, to be simple and efficient.

The bronze alloy bearings have both axial and radial elements to allow extended rotation of the string without damage or wear to the tool or the casing.