Description / Application

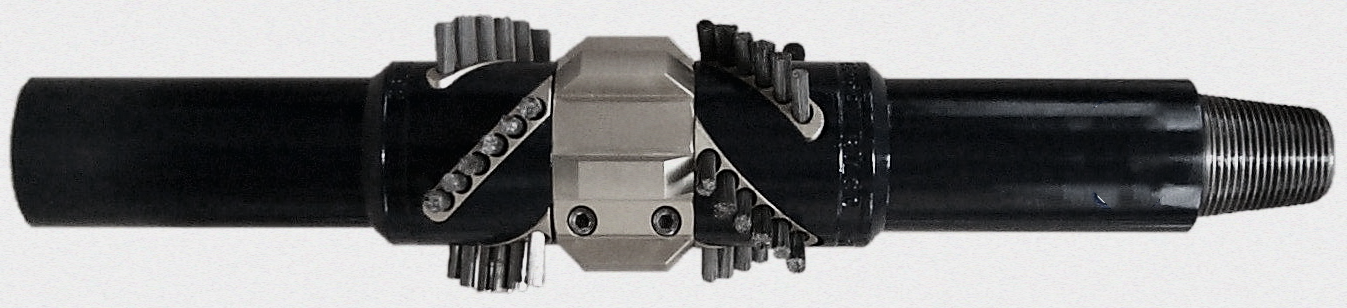

The Sharp Razor(SR) Brush Tools are designed to provide 100% coverage of the inner wall of casing and liners. The 45-degree left and right hand brush blade design is contoured to the exact fit of the casing. Individual brush components are manufactured in house, which allows superior quality control and reliability.

Operation

The Brush Tools is a mechanical aid for all Well Bore cleaning operations. It can be run as a stand-alone device in most drilling or completion operations and is fully compatible with the entire line of SR Well Bore Clean-out Tools. This tool is very effective in removing mud cake, oily residue, cement sheath, and pipe scale. Designed to provide superior contact at all angels of inclination and may be oriented pin up or pin down. The SR Brush Tool is fully rotational and centralized by a non-rotating stabilizerthus protecting against casing wear and enabling long hours of rotation typically associated with fluid exchange operations.

OPERATING GUIDELINES AND TOOL PLACEMENT

The Brush Tool is designed to be run above a full body scraper or spaced in the work string for additional casing coverage on drilling and cleanout/displacement operations.

May be run across open perforations, landing collars, float collars provided the proper dressing equipment (string mill etc.) is run below.

Proper spacing should provide over lapping scour effect to efficiently clean and prepare the casing ID.

FIELD HANDLING GUIDELINES

Screw lifting cap into tool on pipe rack or catwalk to move tool to rig floor. Do not sling tool around brush blades.

Place tool on stump at rotary, install proper crossover on drill pipe and screw together, lower tool into hole and torque connection using snub line to prevent tool damage.

If more than one Sharp Razor tool is utilized in the same string placement it is recommended that this sub assembly be pre-built at the shop to save rig time.

If tools or assemblies are too long, the mouse hole may be used to make connection provided a snub line is used.

Ensure proper lifting equipment and tag lines are utilized when moving pre built assemblies to the rig floor.

The tool or assemblies should be broken out and laid down using the same general handling

procedures used during pick up and make up, except in reverse order.

Prior to running a single tool or assemble the bore should be drifted to ensure that it is clear of any obstruction.

If there is any doubt about the tools fitness for use, a replacement should be requested from Sharp Razor or its authorized agent.

The tool should be returned to Sharp Razor using the same cradle, basket, and thread protectors that were originally supplied.