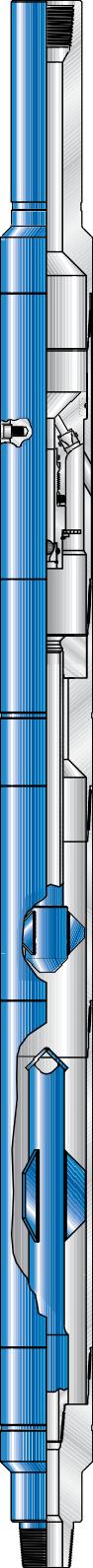

VACS Debris Basket

Capture debris downhole in one trip for reduced NPT

The Sharp Razor vectored annular cleaning system (VACS) debris basket captures debris downhole. It can be used in a variety of applications such as post-perforation sump packer cleaning, one-trip packer milling, and one-trip plug and packer retrieving. VACS technology has an outstanding record of success in saving time and costs through more than a decade of use in wellbore cleanup (WBCU) and fishing operations.

The VACS debris basket consists of a jet bushing, a drive sub, several joints of washpipe, triple- connection bushing, Baker Hughes screen joints and bushing, and a diverter tube and cap. As conventional circulation pushes fluid through the jet nozzles, the VACS system produces a suction pressure at the base of the debris basket. This induced pressure differential pulls any debris from the well into the debris basket.

The VACS debris basket is ideal for keeping small debris from accumulating inside a subsea blowout preventer stack, reaching surface where it can damage rig equipment, or becoming suspended in fluids. The VACS system requires low pump rate, minimizing impact to the formation.

Applications

Vertical, deviated, and horizontal wells

Shallow or deep wells

Deep water

High-pressure/high-temperature environments

Wells with partial or total lost circulation

Wells with fluids exhibiting poor debris-carrying capability

Wells with weak formations

Features and Benefits

Powerful jet bushing

Creates reverse circulation to facilitate debris collection

Washpipe

Forms debris chamber

Can be added to increase debris-carrying capacity

Engineered diverter cap

Deflects debris into debris chamber

Prevents fine debris from reaching the screen