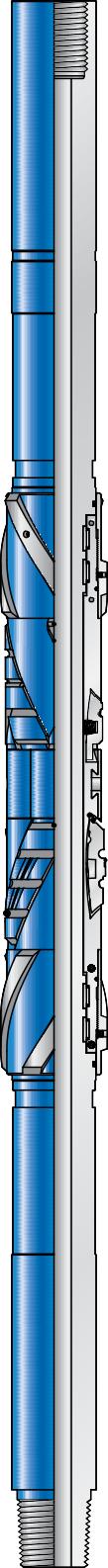

SP Casing Scraper

Achieve effective casing cleaning with high-rotation, high-strength, and larger-flow-area tools

The Sharp Razor SP casing scraper is a durable tool for deepwater, deep, and deviated well applications. It is used to remove mud or cement sheath, perforation burs, rust mill scale, paraffin, and similar substances from interior walls of casing. The tool can be run by itself or as an integral part of a complete wellbore cleaning system with circulation tools, brushes, magnets, filters, and bits.

The casing scraper features one-piece mandrel design without any internal connection. The tensile and torque ratings of the tool are higher than those of the tool joint. This allows the tool to be used in deep wells or deviated wells in which higher tensile and torque ratings are required.

One feature of the tool is its high allowable rotation speed. Allowing drillpipe to rotate up to 150 rpm significantly increases the cleaning efficiency and also allows the tool to be used in the drilling or milling applications in which high rotation speed is required.

The tool also provides large inside diameter and annulus flow areas. It allows for more effective circulation and displacement operations.

The new helical blade design uses both sides and ends of the blade blocks providing more than doubled scraping area than the conventional scraper. The non-rotating blades and stabilizers prevent any excessive wear or damage to the casing when pipe rotation occurs.

Specifications

Tensile rating: higher than the tensile rating of tool joints

Torque rating: higher than the torque rating of tool joints

Allowable rotation speed: 150 rpm

Applications

Deepwater wells

Deep wells

Deviated wells

Extended-reach wells

Wells with high dogleg severity

Features and Benefits

One-piece mandrel design with higher-than-tool-joints tensile and torque ratings

Provides a reliable and effective tool to clean wellbore, and significantly mitigates completion and production risks and costs

Non-rotating stabilizers and scrapers

Effectively cleans well without damaging or wearing casing wall

Highest allowable rotation speed of 150 rpm

Increases cleaning efficiency

Large circulation areas

Improves circulation and displacement efficiency

Spring-energized helical blades with 360° coverage

Increases cleaning surface and circulation area

No exposed fasteners that could vibrate loose

Improves operational reliability