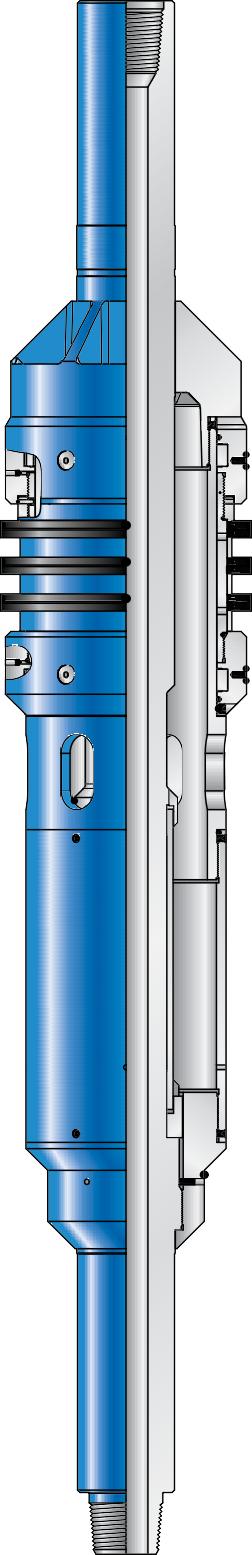

SP Riser Brush and Boot Basket

Clean riser effectively for deepwater applications

The Sharp Razor SP riser brush and boot basket is for deepwater applications used to clean the interior casing wall of drilling and production riser systems. It brushes and wipes mud residue, cement, or other debris from the riser inside wall and recovers them to surface. Recovery is done with a boot basket that is designed in with the brush assembly and built on a robust mandrel that is full drillpipe strength.

The riser brush and boot basket features one-piece mandrel design without any internal connection. The tensile and torque ratings of the tool are higher than those of the tool joint.

One feature of the tool is its high allowable rotation speed. Allowing drillpipe to rotate up to 150 rpm significantly increases the cleaning efficiency and also allows the tool to be run in the same trip with casing cleaning string, eliminating a dedicated riser cleaning run.

The non-rotational brush sleeve and the improved brush robustness prevent wear or damage to the riser inside diameter (ID), while allowing for maximum riser ID cleaning.

The tool has no welding on any non-consumable parts. This feature reduces inspection cost and time in deepwater applications and considerably increases operation reliability.

The basket with built-in magnets captures debris, especially metal debris, effectively. The SP riser brush is ruggedly designed and is ideal for deepwater applications.

Specifications

Tensile rating: higher than the tensile rating of tool joints

Torque rating: higher than the torque rating of tool joints

Allowable rotation speed: 150 rpm

Applications

Deepwater wells

Features and Benefits

Advanced debris/metal debris cleaning capability with built-in magnets

Improves cleaning efficiency

Non-rotating brushes with 360° coverage

Effectively cleans well without damaging or wearing riser wall

One-piece mandrel design with higher-than-tool-joints tensile and torque ratings

Provides a reliable and effective tool to clean wellbores and significantly mitigates completion and production risks and costs

Highest allowable rotation speed of 150 rpm

Increases cleaning efficiency

No welding on any non-consumable parts

Improves operational reliability