By November 23, the second production Plant of Changqing Oilfield had completed treatment of 123 damaged casing Wells, and the recovery rate of production capacity rose from 51.2% to 62.8%.

"From the point of view of casing damage causes, the former external corrosion has gradually evolved into both internal and external corrosion. It is impossible for a single process measure to cure all diseases. Only by classified treatment according to corrosion degree and wellbore fault type, accurate pulse detection and prescription can we improve the recovery rate of oil well productivity and control the increase of casing damage." Li Jianqi, deputy director of the production technology Research Institute of the second oil extraction plant, said.

For solving this problem, two oil production company, in accordance with the whole set of broken blocks the thinking of prevention, according to the characteristics of the corrosion level and different blocks according to the corrosion rate and amount of single well production, emphasizing mainly dosing, process of form a complete set of casing corrosion prevention, daily increase in anode supporting anti-corrosion, annulus partition protection, corrosion inhibitor dosing preventive measures applied, the Jurassic block new TouJing began supporting casing corrosion process.

An operation is a wellbore comprehensive management project. Around two oil production company "restore oil well production and extending the governance" two goals, the establishment of casing damage Wells management work leading group, in the daily management, on the basis of wellbore survey, oil and water Wells is carried out combining with indicator diagrams, such as liquid level data and injection-production corresponding relation, improve and refine of casing damage Wells analysis, record all prospective of casing damage Wells water, salt and other materials, and to provide reliable basis for the analysis of casing damage Wells and governance.

In the process of treatment implementation, we adhere to the fine management of "one well, one method and one process", and combine casing damage well treatment with stimulation measures. According to different well conditions, we mainly carry out classified treatment with LEP isolation, cementing bushing and chemical leakage plugging, so as to deeply dig the reservoir potential. LEP isolation technology was applied to 63 casing damaged Wells with good wellbore condition and low difficulty of isolation and extraction. The production recovery rate was increased by 6.5%, the operating cost was reduced, and the validity of isolation and extraction was extended. For Wells with high isolation difficulty, low recovery degree and high reservoir potential, cementing casing is implemented to reconstruct wellbore and restore well pattern and single well productivity. For Wells that are difficult to isolate and whose casing breaks are concentrated, we will explore new chemical containment tests, innovate the way of plugging agents in casing breaks, and establish a mode of seeking while plugging, so as to improve the success rate and efficiency of plugging, and help maintain stable production and benefit development in old oilfields.

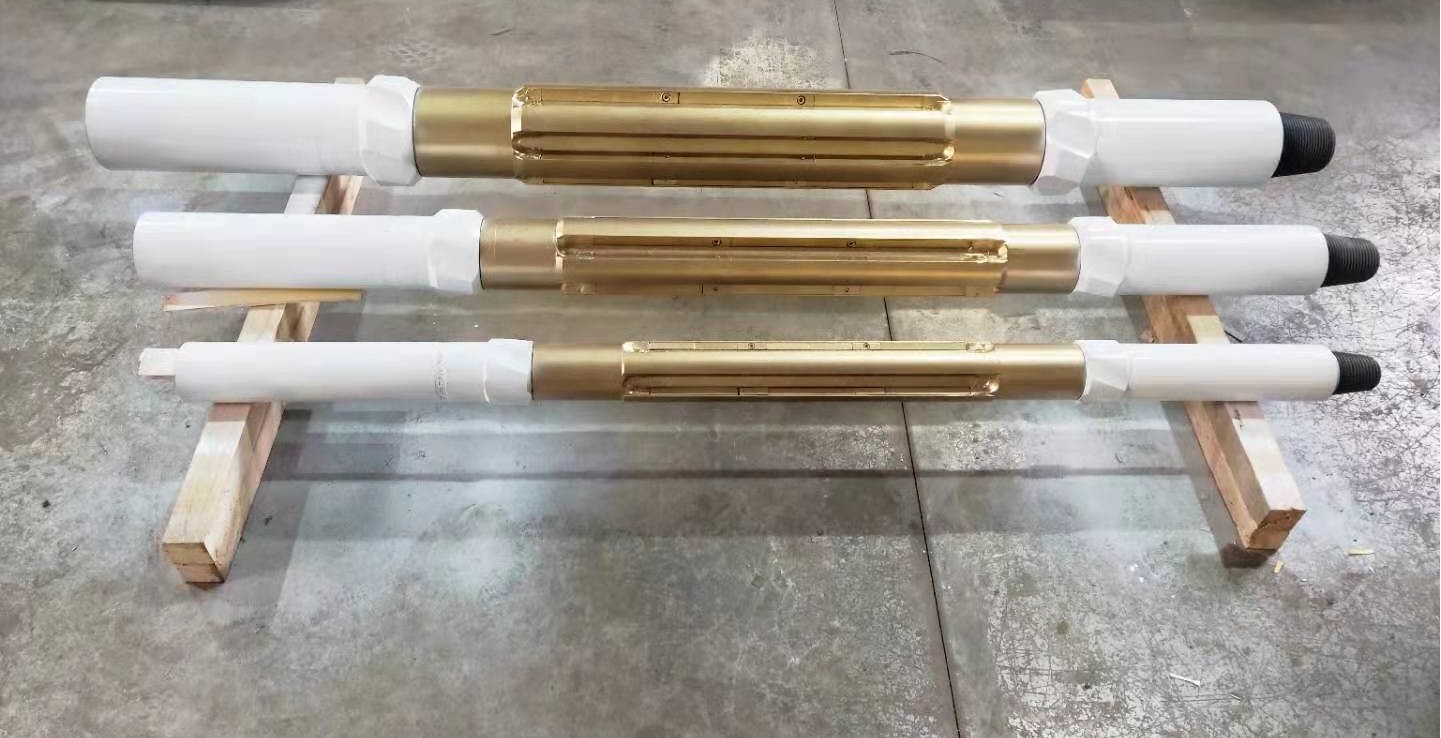

Daily Recommendation: Wellbore CleanOut Tools(Casing Scraper, Casing Brush,

String Magnet)

Contact: jerry@kwoil.cn; linda@kwoil.cn,

WhatsApp/ Tel: +86 151 0293 5475