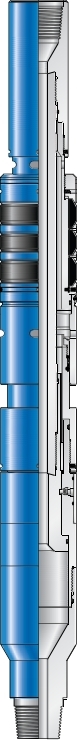

Inflow Test Packer

Perform negative inflow test in same trip as wellbore cleanup operations

The Sharp Razor inflow test packer can perform a negative inflow test on liner tops in the same trip as wellbore cleanup or displacement operations. It eliminates the need for a designated run with a retrievable packer.

The inflow test packers can be set multiple times in one trip, allowing the packer to be tested and an inflow test to be performed. It is usually run on top of the liner top dress mill and below the J-Type circulation swivel.

Set-down weight can be applied to activate the packer to perform the packer test. After the packer is successfully tested, lighter fluid is pumped downhole and the negative inflow test is performed.

Applications

Conventional oil and gas

Liner top integrity test with wellbore cleanup or displacement

Features and Benefits

Allows wellbore cleanup or displacement and liner test to be conducted in a single trip

Saves operational time and cost

Large bypass area

Allows for rapid deployment

Simple to operate, with multiple resets

Reduces operational time

High torque and tensile capabilities

Increases reliability