Wellbore Clean out tools

l Introduction

Wellbore clean out operation is a very important way to enhances operational efficiency by reducing risks caused by cement burrs and debris remained during downhole operation.The whole wellbore clean out operation is a combination of chemical,hydraulic and mechanical process.There are six common operations that need mechanical intervention,including Milling, Shoe track drill-out,Fluid displacement,Perforating,Packer plug retrieval and BOP jetting.A few common wellbore clean out tools include casing scraper,brushes,string magnet,ported sub and valve,basket and Hydrostatic Bailer etc.Different combination of these tools are utilized to complete several goals :introducing solids to the fluid stream,reducing particle size,improving annular velocity,capturing debris and validating wellbore cleanliness .All in all,to protect the well condition and save maintenance costs.

l Why important to clean the wellbore

The remained debris,cement and burrs could more or less influence part of or the whole downhole operation,and even destroy a well in unknown condition.As the cost and complexity of wells increased,people have gradually realized how important to cleanup the wellbore.Most engineers use both mechanical tools and chemicals to remove the debris that interferes with normal operations without damaging the well structure,absolutely reducing costs to an extent.

l Complete wellbore cleanup operational tool

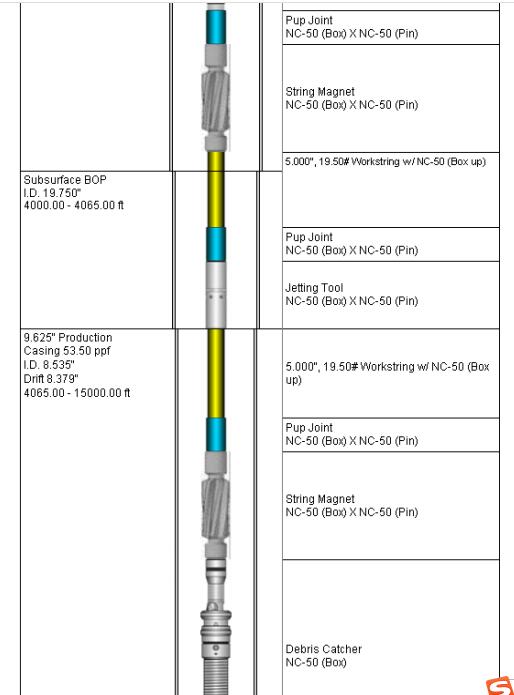

Let’s take Fluid Displacement as an example.The Wellbore displacement is the last step before completion operations commence and can play a big role in the eventual productivity of the well.It is also the only operation than can potentially employ the entire suite of Wellbore clean out tools.

Ø Casing scraper and brushes are utilized to clean the casing wall and introduce solids to the fluid stream

Ø Circulating Valve are often necessary to bosst annular velocities.

Ø String Magnet and Junk Baskets are usually used to capture debris.

Ø Validation tools should be placed in each casing section to completely filter the fluid.

Ø String Mill utilized in reducing particle size is also benificial in some condition

It is worth mentioning that the the failure of the wellbore clean out operation caused by many reasons,On the one hand ,maybe the tool selected don’t match.On the other hand is the condition of the wellbore ,like wellbore geometry,water depth should be taken into account.

Wellbore Clean out tools:

Clean-Out Scraper(s) (Non-Rotating)

Dormant Scraper

Clean-Out Brush(es) (Non-Rotating)

String / Near bit Magnet(s) / Muncher(s)

Ditch Magnet

Waste Retriever / Junk Trapper / Scale recovery tool(s)

Circulating Tool(s) / Ported By-Pass Sub(s)

Multi-Functional Circulating Tool(s) (Drop Ball Based)

Multi-Functional Circulating Tool(s) (Set down weight activated)

Downhole Filter Tool(s)

Full Gauge Stabilizer(s) / Drift Sub(s)

Gauge Mill

Vacuum Debris Removal Tools (AKA: Venturi or Reverse Circulation Junk Basket)

Vacuum Debris Removal Tools Capacity Expansion Chamber

BOP / Riser Cleanout and Jetting Sub Tools

Swivel / Bearing Sub

Landing Sub

main product:

VACTS (Vectored Annular Cleaning Tool Sets)

Drilling Tools & Equipment